1. Description

The DTS-GFJ600 drum coating machine wraps a uniform layer of coating powder on the surface of the product through the rotation of the drum, increasing the amount of powder applied to the product and producing a flake like shape. Suitable for topping block shaped materials (breadcrumbs), such as chicken rice pudding, chicken chunks, fish chunks, Tang Yang series, etc. It is a specialized powder feeding equipment for block, strip, and sheet products, which abandons the traditional method of internal circulation and screening of powder in the powder machine. It has a high yield of uniform powder feeding, low waste powder rate, easy disassembly of various parts, and simple cleaning.

II. Characteristics

Adopting a drum design, the folds and bumps of the product can also be evenly coated with powder;

Achieve a perfect handmade powder appearance, reduce manual labor, and have no dust;

The surface roughness and high coating rate of boneless and boneless products result in a golden scale effect;;

A unique screening device separates large particles generated during the production process, resulting in a perfectly dispersed product at the discharge end;

The opening and closing lifting screw makes the cleaning process simpler;

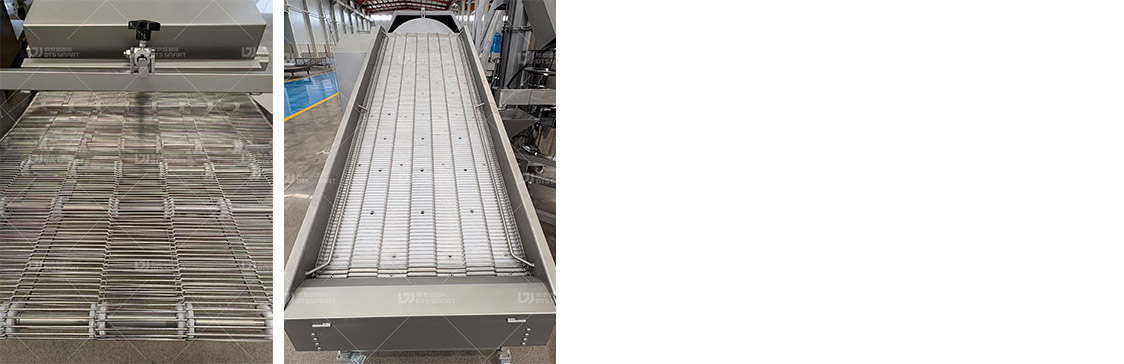

According to the product type, the conveyor device can be selected from: unit belt, PUF belt, stainless steel B-type spiral mesh belt;

We can also customize powder coating for tunnels; Roller powder (multi roller) integrated machine;

Controllable powder loading rate and appearance, adjustable bottom powder thickness, drum angle, and drum speed;

Dust collection system, automatic powder replenishing machine, vibrating hopper (optional);

III. Technical Parameters

Model: DTS-GFJ600;

Conveyor belt speed range: 4~20m/min variable frequency speed regulation;

Input height: 1050+50mm;

Output height: 1050+50mm;

Power: 3.5kW;

Mesh belt width: 600mm;

Dimensions: 5410 * 2050 * 1750mm