1. Description

When the DTS-SFJ tunnel type powder feeder passes through the conveyor belt, the covered powder conveyor belt and the scattered powder on top are evenly coated with a layer of pre powder or mixed powder to meet the requirements of the next process. It can be connected with the sizing machine and the upper chip machine to form production lines for different products. Thus completing the processes of powder, slurry, powder, slurry, powder, and slurry, powder, slurry, and powder.

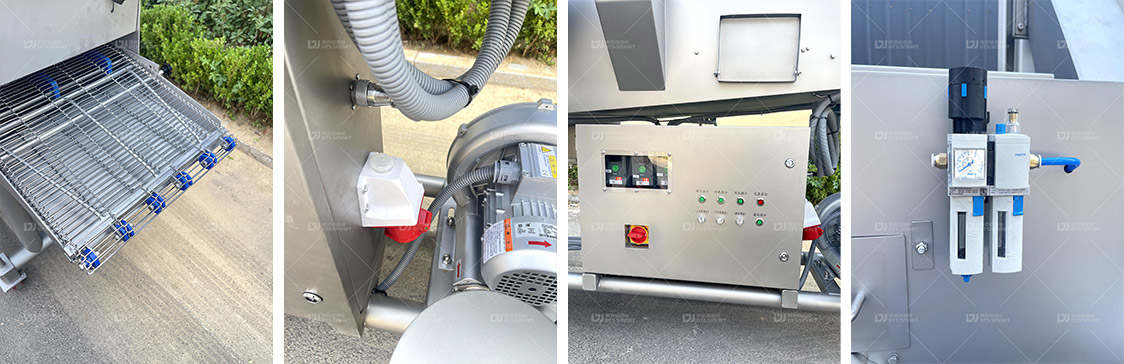

II. Characteristics

The thickness of the upper and lower powder layers can be adjusted;

Powerful fans and vibrators to remove excess powder;

Easy to operate and adjust;

Special mesh belt powder spreading technology, uniform and reliable;

The opening and closing screw makes the cleaning process simpler;

Specially designed screw lift, suitable for different mixed powders, corn starch, potato starch, and coating powders;

Having reliable safety protection devices;

Using SIEMENS electrical components for safety and reliability;

The whole machine is easy to clean and meets HACCP requirements.

III. Technical Parameters

Model: DTS-SFJ400, DTS-SFJ600, DTS-SFJ1000;

Conveyor belt speed range: 4~20m/min variable frequency speed regulation;

Input height: 870-970mm;

Output height: 1000+50mm;

Power: 2.93kW, 2.93kW, 4.9kW;

Mesh belt width: 400mm, 600mm, 1000mm;

Dimensions: 2655x835x2150mm, 2655x1035x2150mm, 2655x1435x2150mm